Unknown Facts About Double Glazing Panel Replacement

Table of ContentsOur Double Pane Tempered Glass Panels IdeasTop Guidelines Of Double Glazing PanelsFacts About Double Glazed Glass Panels Prices UncoveredDouble Glazed Glass Panels Prices Fundamentals Explained

If contemporary appearance of standing seam metal roof is not specifically proper for your house, after that you can go with steel tiles roof that functions well for historic structures, and also provides the traditional want to your roofing system.

The panels are readily available from.016 to 3/16 (.1875) of an inch, using Light weight aluminum, Stainless-steel, Galvanized or ACM. Whatever the thickness, product or surface Emburite Panels will respond to the demand.

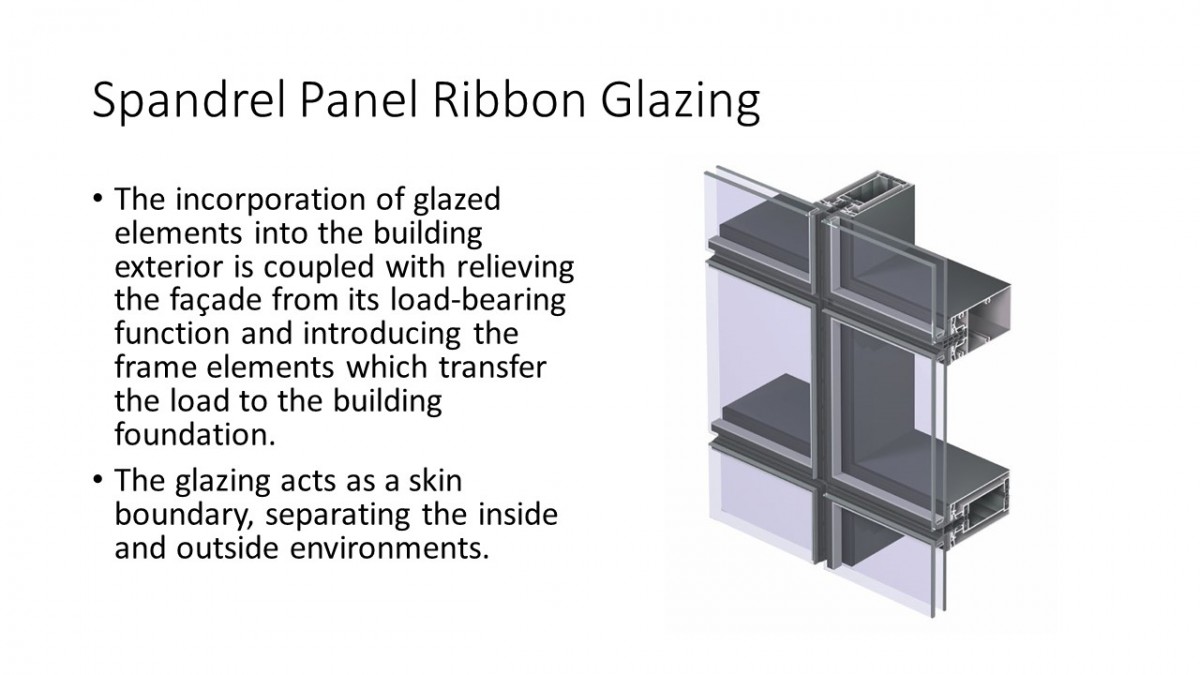

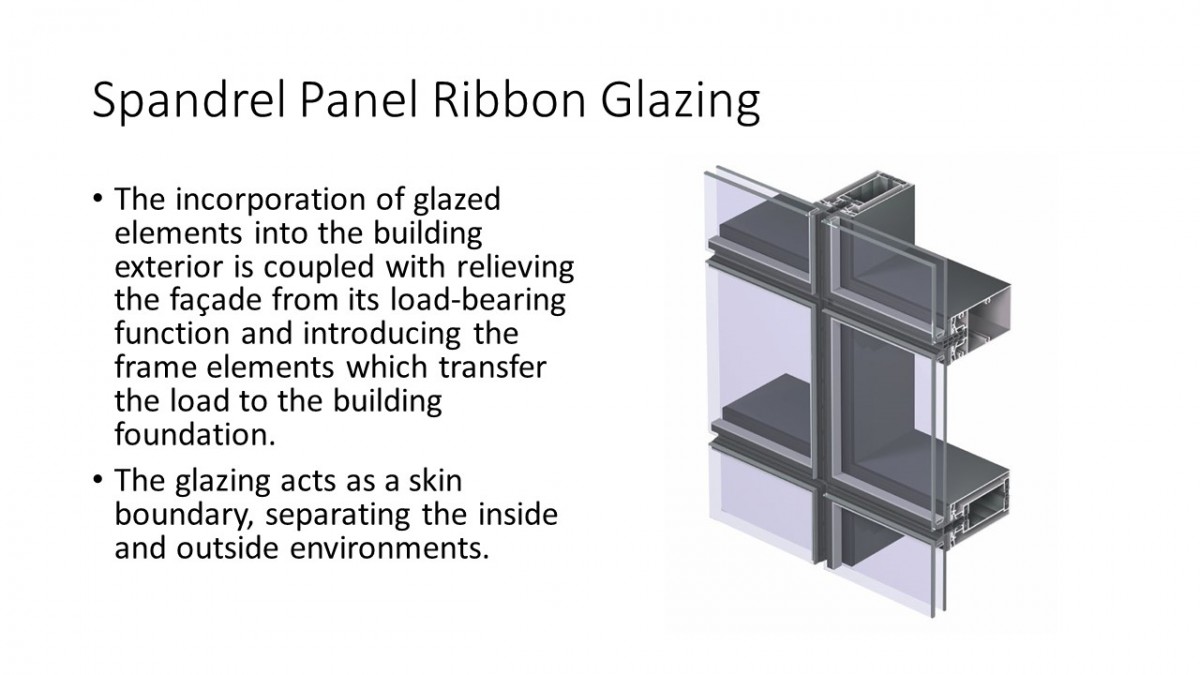

The very first major instance of the design was the Equitable Savings & Loan Structure in Rose city, Oregon carried out by designer Pietro Belluschi in 1948. As the world's first completely enclosed cool structure, this sleek 12-story framework quickly set the pattern for lots of post-WWII high-rise buildings as well as little scale workplace buildings. The curtain wall system is included a repeated grid of upright extruded light weight aluminum mullions as well as straight rails.

Double Glazing Panel Replacement - An Overview

These spandrel panels can can be found in a range of products. Early spandrel panels were made of heat-strengthened opaque glass integrated with tinted ceramic. The Pittsburg Plate Glass Business produced the glass panels under the brand name "Spandrelite," and supplied 8 common shades. The Libbey-Owens-Ford Corporation sold sixteen shades options under the "Vitrolux" brand name.

Thought about ideal for virtually any kind of dimension commercial, federal government or institutional building, the Drape Wall surface style ended up being prevalent by the very early 1950s. Lots of post-WWII buildings of differing styles additionally integrated drape wall systems right into some facades but are not taken into consideration Drape Wall surface style unless most of the visible facades are so created (fire rated glass panels).

Curtain wall surface as well as shop glazing systems are usually a slim, non-structural external faade aspect of a structure that can cover several floors or be included into a punched opening. Polishing systems operate largely as air and also water vapor barriers, resisting air or water infiltration and also fit structure and system activity generated by wind, thermal, and also seismic pressures.

Therefore, lightweight materials can be used in their advancement. Industrial glazing systems are normally constructed of aluminum-framed walls with glass, steel panels, louvers, operable home windows or vents, or stone veneer infills. Building envelope professionals will typically recommend developers on drape wall as well as shop needs for building movement, thermal growth and also tightening, water diversion, and thermal effectiveness.

The 6-Minute Rule for Double Pane Tempered Glass Panels

Condensation development on spandrel infill is probably to happen throughout severe winter problems when insufficient warmth is provided from the panel glass was decor interior to avoid interior infill surface temperature levels from staying over the dew factor. When interior surface temperatures dip listed below the humidity, water particles begin to base on the interior surface area of the spandrel infill - double glazed panels online.

This dampness can be soaked up by the surrounding elements, creating damages to the assembly and adjacent surfaces. As condensation establishes in these unventilated locations, microbial development may create and also infect nearby areas, causing more damage. Condensation build-up in these areas can harm glazing spandrel coverings. Furthermore, mixes of these types of damages can happen, causing modern damage that will certainly require specialist removal.

One method to postpone the development of condensation on the glazing system spandrel infill is to utilize the building HEATING AND COOLING system. By enhancing airflow near these areas, more warmth will be transferred to the setting up and rise indoor surface area temperature levels. Another way to use the COOLING AND HEATING system is by lowering the interior family member moisture set points relative to outside temperature.

Another method of deterring condensation is by securing the horizontal-to-vertical mullion joints at the spandrel dental caries to stop unrestrained air migration right into the cavity. Typically, an uncontrolled inside is moisture loaded as well as when it comes into contact with the spandrel infill, which is listed below the dew factor, it raises the amount of condensation formation.

How Double Glazing Panels Cost can Save You Time, Stress, and Money.

Along with integrating rehabilitation technique, ways to reduce condensation potential throughout design include: Usually drape wall systems have greater resistance to condensation than shop systems. Making use of drape wall is one way to lessen, or delay the start of condensation formation. At Pie, we supply 2-D thermal modeling (THERM) to help our clients with the layout of spandrel locations. double glazing panels.